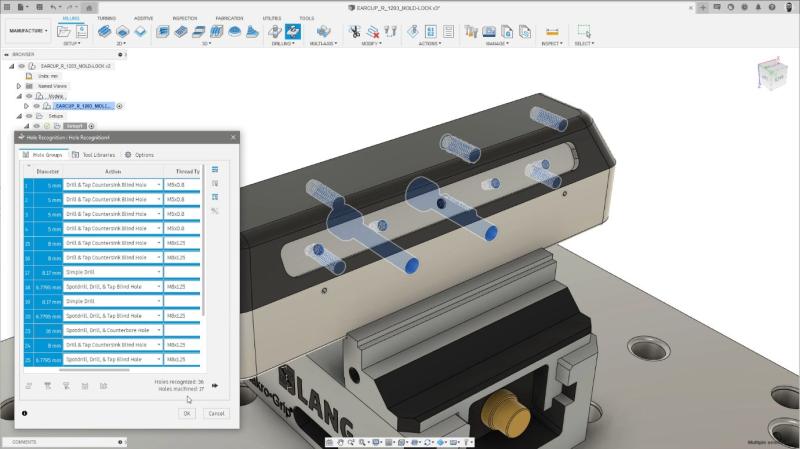

The digital factory concept is transforming the manufacturing landscape, integrating digital technology into every facet of production. This revolution is not just for the industry giants; it's especially crucial for SMEs, helping them streamline operations, slash costs, and speed up product development. But let's face it, revolutionizing your manufacturing process can feel like a Herculean task, especially when resources are tight and every decision counts. That's where we come inOur Design and Manufacture package is the ally SMEs didn't know they needed. With Autodesk Fusion at its core, we're offering more than just software; we're offering a gateway to the future of manufacturing. Imagine having the ability to design, simulate, and produce all in one place. From intricate 3D designs to the nitty-gritty of CAM tools, we've got it all covered. But we didn't stop there. We're not just selling a product; we're fostering a community of innovators ready to take on the challenges of tomorrowWe're here to make sure that the path to digital transformation is not just accessible but achievableIn the dynamic world of design and manufacturing, staying ahead means embracing change and innovation. Autodesk's Bold VisionAutodesk has long been a beacon of innovation, guiding the design and manufacturing industry towards a more integrated and efficient future. Their development of the Autodesk Fusion Industry Cloud is a game-changer, offering a seamless blend of design, engineering, and manufacturing processes all in one platform. The beauty of Autodesk Fusion lies in its ability to simplify complex processes. Imagine converting 3D models into 2D documentation with just a few clicks or using AI to automate the creation of toolpaths. This isn't just about saving time; it's about unlocking new levels of creativity and efficiency. And with Autodesk's strategic move to acquire FlexSim, the dream of a fully connected digital factory is closer than ever. This integration promises to revolutionize how we understand and optimize manufacturing workflows, making "efficiency" more than just a buzzword. Multiaxis Journey with AutodeskAt Multiaxis, we see ourselves as more than just a company; we're a community of innovators, thinkers, and makers. Our mission has always been to bring the best of technology to our clients, and Autodesk Fusion is at the heart of this mission. We're not just selling software; we're offering a vision of what the future of manufacturing can look like. A future where design and manufacturing processes are so intertwined, the possibilities for innovation are endless. Our role goes beyond providing tools. We're here to guide, educate, and support our clients as they navigate the complexities of modern manufacturing. By embracing Autodesk's technologies, we're helping our clients not just to survive but to thrive in a competitive market. Looking ForwardThe road ahead is exciting. As we continue our partnership with Autodesk, we're constantly looking for new ways to bring the transformative power of the Autodesk Fusion Industry Cloud to our clients. We're committed to staying at the forefront of technology, ensuring that our community has everything they need to succeed.

We're on a journey towards a more innovative, efficient, and collaborative future, and we want you to join us. With Autodesk Fusion, the possibilities are limitless. The story of Apiar, a British company utilizing additive manufacturing through Fusion to create optimized and sustainable components for watch manufacturing, is a prime example of such innovation. Their approach not only showcases the potential for additive manufacturing in producing intricate, high-quality components for horology but also highlights the broader applicability of these techniques in enhancing sustainability and efficiency across various manufacturing designs. Sharing Apiar's journey and achievements serves as an inspiration and a beacon for exploring how additive manufacturing can be leveraged beyond traditional boundaries, aligning with our commitment to innovation and excellence in manufacturing at Multiaxis 🕒 Custom Timepieces, Sustainably CraftedApiar's journey from concept to brand has been marked by a commitment to sustainability and precision. Their custom timepieces, which take 4-6 months to manufacture, are a testament to their dedication to quality and environmental responsibility 🛠️ End-to-End Product Development with FusionUsing Autodesk Fusion, Apiar has streamlined their product development from design to production. The ability to design, render, simulate, and manufacture within a single platform has been crucial for their intricate watch cases, receiving valuable feedback from watch collectors along the way 🌱 A Sustainable Future in HorologyApiar's use of additive manufacturing not only optimizes the production process but also aligns with sustainable practices, reducing waste and energy consumption. This approach is not just about creating timepieces, but also about preserving our planet for future generations. For a deeper dive into Apiar's pioneering work in watch manufacturing and their use of Fusion, check out this insightful profile: Apiar: Finding Time Excited to share that our Complete Mill & Turn series now includes the Autodesk Fusion Manufacturing Extension, which offers much more than just 5-axis machining capabilities. This powerful extension provides users with advanced sheet metal nesting, additive manufacturing tools, and a suite of other advanced features to enhance productivity and innovation.

Discover how these tools can transform your manufacturing processes and drive project efficiency. Learn more about the top capabilities of the Autodesk Fusion Manufacturing Extension in this insightful post from the Autodesk Fusion blog. A Role That Shapes the FutureThe Integration Specialist at Multiaxis is a position designed for individuals who are passionate about technology and eager to make a tangible impact in the manufacturing sector. This role is perfect for someone who thrives in a dynamic, high-tech environment and is motivated by the challenge of integrating cutting-edge machine tools into our Fusion product library What You'll Do

Who We're Looking ForWe're seeking candidates with a strong foundation in computer knowledge, and a deep understanding of CNC machining, manufacturing processes, and terminology. Experience in CAD 3D modeling and CAM software is essential, along with excellent communication skills and a professional demeanor. Compensation and OpportunitiesThis part-time/contract position offers competitive compensation, with the potential to transition to a full-time role. We believe in rewarding our team members fairly and providing opportunities for career growth. Join Us

Apply NowDon't miss this chance to be part of a company that's shaping the future of manufacturing. Visit our careers page at Multiaxis Careers to learn more and submit your application. We look forward to discovering how you can contribute to our success!

|

@multiaxis_llcWritten by Archives

July 2024

|

RSS Feed

RSS Feed